- PERMANENT-CLEAN automatic soil removal: innovative filter system eliminates manual pre-cleaning. Soil is immediately removed into an external strainer, which saves operating costs and protects the machine

- VISIOTRONIC-TOUCH control: colour touchscreen (displays text and graphic) in conjunction with single-button control and remaining cycle time indication

- WASHSMART app: controlling your warewash operation with smart technology: status and messages, usage and operating costs, hygiene, service and consumables order

- SENSO-ACTIVE resource management: constantly measures the quality of the wash water and keeps the amount of rinsing needed in each rinse cycle to the minimum in order to guarantee a fully hygienic wash result

- Eco programme: switchable steam rinse cycle reduces fresh-water consumption to 1.4 l/cycle. Saving of up to 44 % water and chemicals

- VAPO-ACTIVE steam washing: significantly less manual pre-cleaning and second runs by intensive wash cycles with steam

- POWER-PLUS wash programme: selectable high-pressure programme to wash heavily soiled wash itemsyExhaust energy storage: the fully enclosed 4-sided hood keeps steam and energy inside the system: energy saving up to 3 kW, less humidity in the kitchen area and better hygienic conditions

- CLIP-IN wash and rinse arms: wash and rinse arms can be removed with one hand and without any tools

- ROTOR-X wash system: separate rotating upper & lower 4-spoke wash arms deliver dynamic wash power

- VAPOSTOP (optional): prevents vapour escapingfrom the machine when the hood is opened

- Intelligent energy management: the available energy is used continuously. Thus, at a low total loading value the heating time gets reduced

- Interlocked strainer: prevents operation without tank strainer

- Optional refill signal: monitors contents of external chemical containers

- EASY-CLEAN concept: blue markings in the machine help the operator to identify the components which require cleaning

- Thermolabel 71 °C: default temperatures setting acc. European DIN can be switched by operator to a higher thermolable setting

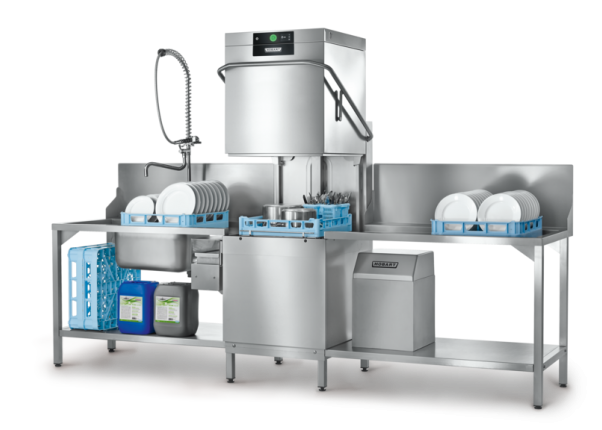

- Hood-type dishwasher with switchable high pressure wash for straight through or corner operation

- Nominal capacity up to 70 racks/h or 1,260 plates/h or 2,520 glasses/h

- 8 automatic cycles: short, standard, intensive, eco, cutlery, starch-removal, permanent, hygiene

- Multi-Setting: booster capacity may be reduced from 12.4 kW to 6.2 kW if connected with hot water

- Heat and noise insulated hood

- Strainer soil sensor

- Integrated Wi-Fi Module

- Self-cleaning programme

- USB-interface for comfortable download of operational data

- Ready to install - completely equipped: fill / drain hose, electrical cable, detergent dispenser, rinse aid dispenser, rinse pump, drain pump, back-flow preventer

- Tank, frame, wash / rinse arms and panels are stainless steel 1,4301

- 2 plate racks P-18-12

- 1 universal flat rack B-00-07

- 1 plastic cutlery rack CB8

VARIANTS

| Order number |

Description |

| AUP-10B |

Basic model

AC 400/50/3N

|

| AUPS-10B |

with integrated water softener

|

TECHNICAL DATA

| Cylce times* |

52 / 70 / 170 / 180 sec.and special cycles |

| Water consumption |

1.4 l/rack |

| Tank capacity |

40 l |

| Tank heating |

2.5 kW |

| Power supply |

400 / 50 / 3N |

| Booster loading - Standard |

12.4 kW |

| Booster loading - Alternative |

6.2 kW |

| Total loading - Standard |

17.0 | 3 x 35 A |

| Total loading - Alternative |

10.8 | 3 x 25 A |

| Wash pump |

1 x 1.1 kW + 0,7 kW |

| Rack size |

500 x 500 mm |

| Loading height |

440 mm |

| Noise level |

66 dB (A) |

| Weight (gross / net) |

160 / 140 kg |

*Thermostop guarantees required temperatures with cold water connection, the actual cycle times extend accordingly.

For corner operation we recommend to make the right side of the machine accessible for service.

For machine protection the water hardness should not exceed 1°dH, if higher we recommend using an integrated water softener or a HOBART HYDROLINE water treatment system.

ACCESSORIES

| Order number |

Description |

| 04-006330-001 |

Low level chemical sensing lance set 450 mm for external containers (up to 20 litre)

|

| 04-006330-002 |

Low level chemical sensing lance set for external containers (up to 10 liters or limited height)

|

| SEF-19/096 |

VAPOSTOP for AUP(S)-10A

prevents vapour escaping from the machine when the hood is opened

|

| SEF-19/113 |

Automatic hoodlift for AMX(S)/AMXX(S)/AUP(S): closes the hood by pressing the start button and opens automatically at the end of the cycle (loading height: 440 mm, back panel is included)

|

| SEF-19/106 |

Back panel

(if unit is not installed against wall. All units have closing frame to wall at rear)

|

| ML71726 |

Corner splash panel

for open distance to the wall in case of corner installation

|